Baseboards

The baseboards were made in the open frame format. Open frame baseboards are used by mainly more experienced modellers as they are more complex than the standard baseboard. They consist of thin ply uprisers that shaped to the lay of the land on the layout. Obviously this needs some forward planning so you can mark out the height any hills on the layout.

On this layout, they were used simply because they are very lightweight and it was something that I hadn't thought about trying beforehand. Once all the uprisers have been cut out, you need to brace them with wooden battens between each of the uprisers to provide strength. Polystyrene is then fitted between the uprises and shaped to the contours of the land.

One piece of advice after having suffered track problems - lay the track on a piece of ply or MDF for the trackbed bolted onto the baseboard.

Track

The track is mainly from Peco and the track formation includes the end of a run around loop (the other end assumed off-stage) and a curved point leading into two sidings. A further siding at the rear runs directly in front of the hangar with very limited clearance.

A recent extension onto the left hand end has meant the inclusion of a spur for the loco shed which helps hide the scenic exit. Narrow gauge track is again Peco but is actually N gauge - I'm hoping to purchase some 'Crazy track' (narrow gauge sleeper spaced track) in the near future. I must also note that currently all the track is insulfrog but I really think it would be worth buying electrofrog points for the new version of the layout simply because I use a lot of 4 wheeled locos that often stop on the dead frog.

Electrics

The electrics on RAF Calshot are very simple! There are only three feeds on the layout to make things easy; one on the loco shed line, one between the curved point and crossover and a final one on the rear line on the extension. These three feeds meet together via a block connector and go directly into the standard Gaugemaster Combi unit.

Of course, in an ideal world I would be using DCC control, but the expense has been the main flaw.

Structures

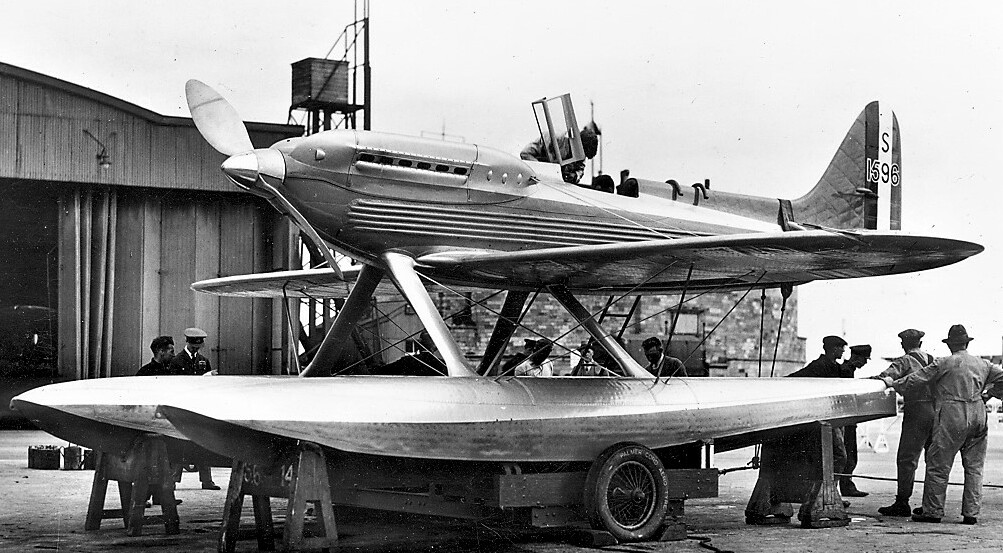

For a small layout, there are quite a few buildings on the layout. The main building is the Seaplane Hangar. This was built out of one pack of Wills corrugated asbestos sheeting. The dimensions were helpfully obtained from looking at prototype pictures and then working out of the real thing before scaling it down. RMweb was very helpful in gaining inspiration for the layout and there was one chap so kindly gave me copies of photographs of hangars that were based on RAF Calshot. See here: RMweb - Forum

The next building is the Cafe. This was modified from a Wills platform shelter. First, the inside partition wall was separated and then the gable cut off and retained for filling purposes later. The partition wall was then glued as part of the outside, filling the gap where the bench was. The left over gable end was then used to hide the resulting gap between the newly glued partition wall and the end wall.

The next structure is the loco shed. As with most of the structures this was built out of mainly Wills plastic sheets. A pack of brick sheet was bought and then marking out could commence. Measurements were actually determined by the size of the sheets which fortunately meant tank locos could just about fit in. A hole was cut using a sharp craft knife (Usual safety warnings here folk!) and a window manufactured from thin perspex (out of a cereal box or something similar) white self adhesive white label cut into thin strips and carefully applied to the perspex to form the window frames. The rafters would be visible from the outside so I decided to make some from matches, it worked better than expected and can be viewed from the skylights in the roof. The roof itself was made of Slaters corrugated iron sheet, I chose it because it is thin - just like the real thing. This is vital because the thickness would be easily visible. The whole piece was made around a piece of Wills corrugated glazing to form the skylight. Clerestory ventilation added using more Slaters sheets.

In my opinion, one thing that really spoils a good layout is the amount of RTR kits used that are instantly recognisable - however, it really is so easy to just modify them, even if it just means adding guttering or drainpipes, or even just painting them! So often people tell me they can't scratch-build - when asked how much have they done the result is always 'Very little'. I think that some modellers are almost scared of committing themselves to scratch-building. I can see why, but you're never going to learn if you don't try it once in a while. So what are you waiting for? Give it a go - there are always people out there to help you.